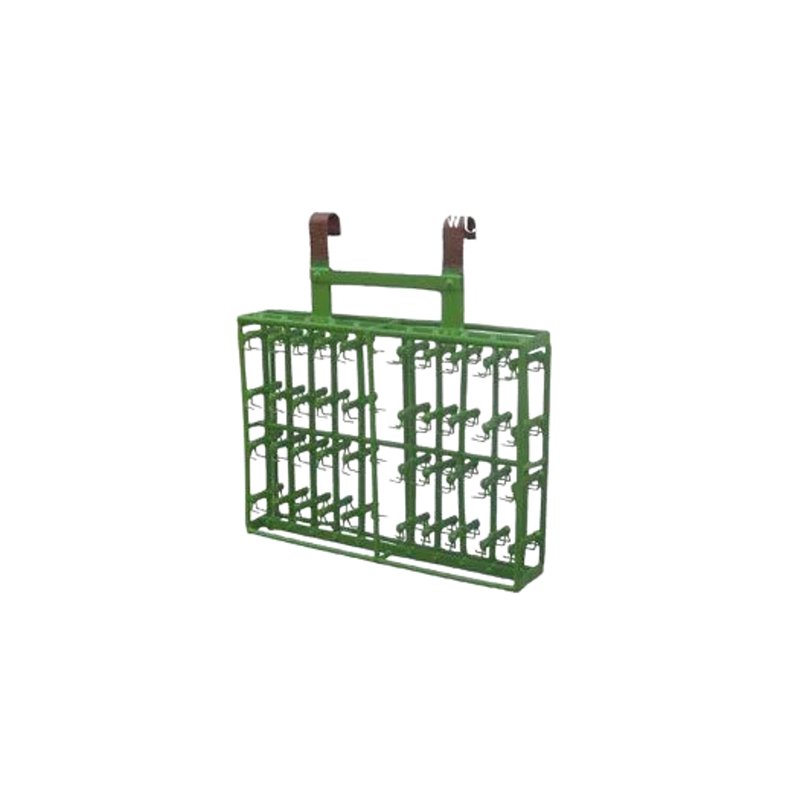

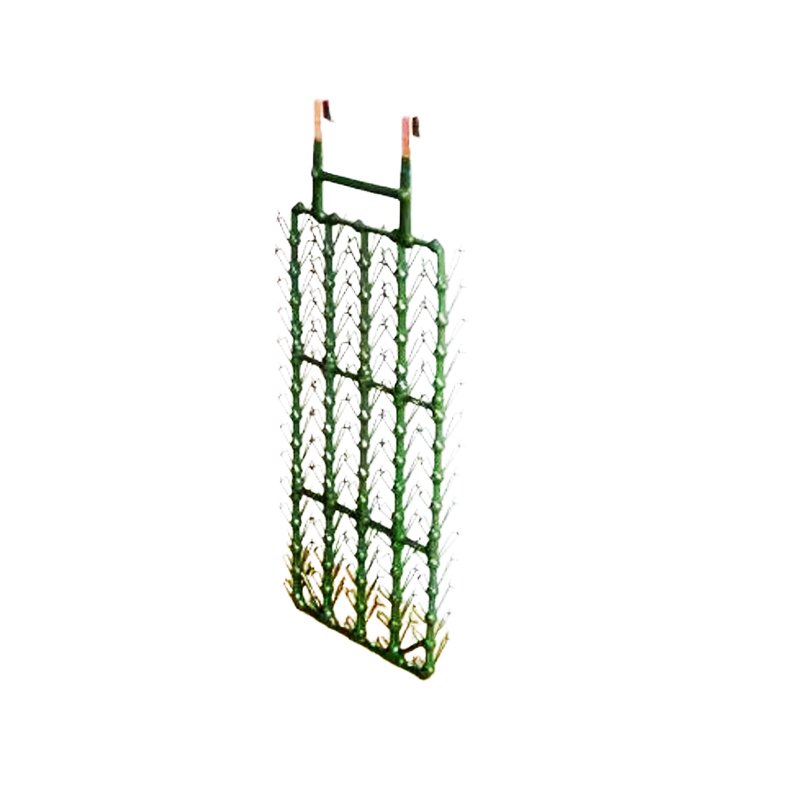

Plastic Electroplating Tooling Manufacturing Plating Hanging Tool

| Material | Steel, stainless steel, copper, bowl, brass, phosphor bronze |

|---|---|

| Sample Leadtime | 2 Days |

| Production Leadtime | 7 Days |

The Certificates We have

Details About Plastic Electroplating Tooling Manufacturing Plating Hanging Tool

Plating Tools

There are different types of electroplating racks depending on the shape of the part, the technical requirements of the plating, the plating process, and the size of the equipment. For example, there is a difference between automatic thread and manual thread. Usually, electroplating workshops prepare general racks suitable for various common parts and special racks designed and produced only for certain parts. There are many types of universal hangers, suitable for a variety of processes and parts.

The structure of the rack

The structure of the hanger is generally relatively simple, consisting of five parts: a hook, a lifting rod, a main rod, a support rod, and a hook.

The hook is the connection structure between the hanger and the rod. It transmits current to the hanger and parts during electroplating. Therefore, it must be made of materials with good conductivity. The hook and pole should maintain a large contact surface and good contact to ensure smooth passage of current. Its cross-sectional area is equivalent to the cross-sectional area of the same material as the main rod of the hanger. The hook must bear the entire mass of the hanging fixture and plated parts, so it is required to have sufficient mechanical strength. The hook and the main rod are usually made of the same material. The two can be made into one piece or made separately, and the hook and the pole are connected to the hanging device by brazing or other methods. For hangers made of steel or aluminum alloy, the hooks are generally made of copper or brass, and the connection methods can be riveted and welded. Its size should be designed according to the diameter of the cathode rod to make the hanger easy to operate when hanging and removing it.

The lifting rod is located at the upper part of the main rod is perpendicular to the main rod, and is connected to the main rod by welding. When the hanger is hung in the plating tank, the position of the lifting rod should be about 80 mm higher than the liquid level. Use the lifting rod to lift the hanger during operation. It should have sufficient mechanical strength, and the cross-sectional area is generally the same as or slightly larger than the support rod. The main rod supports the weight of the entire hanger and hung parts and transmits current to each support rod and part through the main rod. The material of the main rod is generally φ (6~8) mm brass rod. The support rod is usually fixed on the main rod by the welding method and bears the weight of the suspension parts during operation. The material of the support rod is generally φ (4~6) mm brass rod.

Hooks are generally welded on the support pole, sometimes also on the main pole, and are used to hang or clamp parts. The materials are generally steel wire and phosphor bronze wire.

The distribution density of hooks on the hanging device should be appropriate. Most of the important surfaces of the parts on the rack should face the anode, and overlap should be avoided. Generally, the distance between small and medium-sized plated parts is (15~30) mm, and the distance between cup-shaped plated parts is generally 1.5 times the diameter. According to the different connection methods between the hook and the plated parts, the hook is divided into two types: hanging type and clamping type.

(1) Suspension hook. Plating parts and hooks generally adopt the free-hanging method. That is to say, the hook is hung in the hole of the part or at an appropriate position. After the part is hung, it can move without falling off, and its contact point can be changed when the hanger is shaken. This kind of hook is easy to install and remove, and the mark of the hanging device is not obvious on the plated parts. When the current density in electroplating is small, the free suspension method is generally used.

(2) Clamping hook. The connection between the plated parts and the hook relies on elastic contact. Generally used in bright electroplating, chrome plating, and other occasions or when using a larger current density. It uses the elasticity of the hook to clamp a certain part of the part and relies on contact pressure to make it conduct electricity well. The strength of the elasticity is determined by the material used for the hook, wire diameter, wire length, board width, and board thickness.

No matter which method is used to hang the parts, it should be ensured that the gas generated during the electroplating of the parts is discharged smoothly to prevent the gas generated from accumulating in a certain part to form an “air pocket” and affecting the quality of the coating. For example, when parts with blind holes and concave shapes are hung, their mouths should be tilted slightly upward, and plastic parts should use multiple contacts to make contact with the hooks. In short, the form of the hook and the way of hanging is determined by the shape of the part and the electroplating process conditions.

Bright Chrome is a Polished Chrome finish color. Chrome’s reputation for quality arises from the fashion for pure, contemporary lines. It gives the Coffee Machine Parts a sparkling which never dulls over time. Its versatility makes unlimited creativity possible when it comes to decorative touches.

Chrome Plating is created over a thick nickel underlay. It is a durable finish which is virtually impervious to wear or scratches. Its resistance to corrosion and common Coffee Machine products make it a benchmark in Home appliance decorations.

- Cleaning: Very easy

- Corrosion resistance:unexceptionable

- Scratch resistance: unexceptionable

- Resistance to cleaning products: unexceptionable

Share Plastic Electroplating Tooling Manufacturing Plating Hanging Tool With Your Clients

Available Shipping Method

Ship By Air

Ship By Sea

Ship By Train

Ship By Express