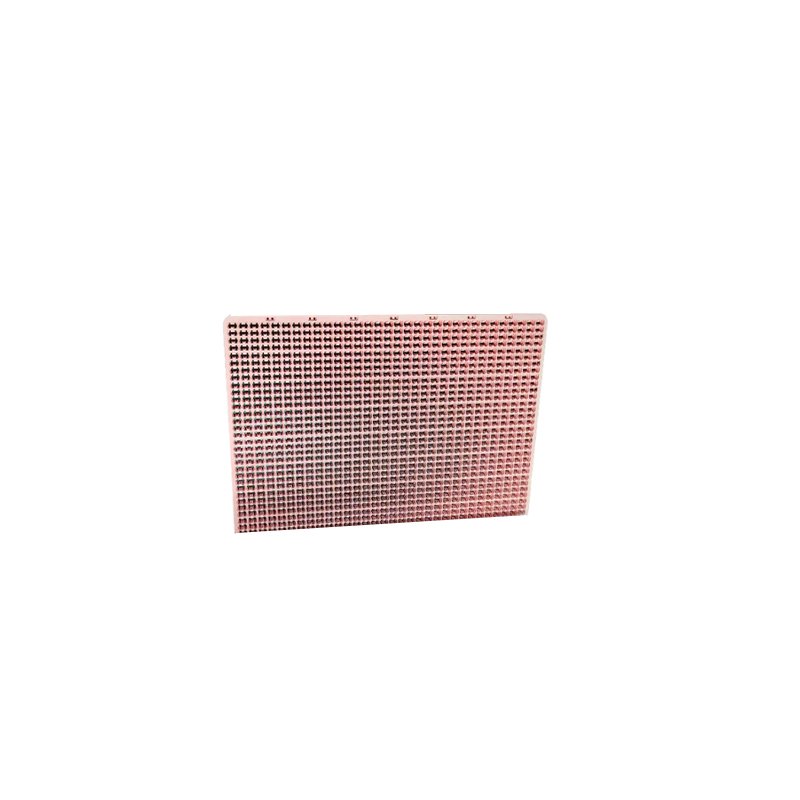

Electroless Copper Plating Plastic Panel | Chemical Copper Plating Plastic

| Material: | ABS, ABS+PC, NYLON, PC, PE, FPI |

|---|---|

| Process Might be Used | Brushing, Shielding |

| Mimimum Order Quantity | 10000pcs per Item for Bulk Order, 1000pcs per Item for trial Order |

| Sample Leadtime | 3-5 Days |

| Production Leadtime | 10-20 Days |

The Certificates We have

Details About Electroless Copper Plating Plastic Panel | Chemical Copper Plating Plastic

Principle of chemical copper plating

Chemical copper plating is the reduction and precipitation of copper ions on a catalytically active surface by the action of a reducing agent:

Reduction (cathodic) reaction: CuL2+ + 2e- → Cu + L

Oxidation (anode) reaction: R → O + 2e-

Therefore, the main reaction formula for chemical copper plating using sodium hypophosphite as a reducing agent is: 2H2PO2- + Cu2+ + 2OH- → Cu + 2H2PO3 + H2↑

In addition to being thermodynamically established, the chemical reaction must also meet the kinetic conditions. Chemical copper plating like other catalytic reactions needs heat energy to make the reaction, this is the chemical plating solution reaches a certain temperature before the plating speed of the reason. Theoretically, the rate of chemical copper plating can be expressed by the rate of increase in the concentration of reaction products and decrease in the concentration of reactants. Since the chemical copper plating solution used in practice contains certain additives, its presence creates too many influencing factors and the situation becomes too complicated. As a result, most studies of the kinetics of chemical copper plating reactions begin by limiting themselves to the most basic components of the plating solution.

Uses of Chemical Copper Plating

During chemical copper plating CU2+ ions are reduced to metallic copper by gaining electrons, and the reducing agent gives off electrons and is itself oxidized. The essence of the reaction is the same as the electrolysis process, except that the process of gaining and losing electrons is carried out in a short-circuit state, and the flow of current is not visible from the outside. Therefore, chemical plating is a very energy-efficient electrolytic process because it does not have an external power supply or electrolysis, and there is no resistance voltage drop meteoric consumption. A simple example can be proved: chemical copper plating can be discharged at intervals of 5-10mm distance from the printed circuit board, once immersed in the chemical copper plating solution for copper plating, while the plating method can not be done. Chemical copper plating can be deposited on any non-conductive substrate, the use of this feature in the manufacture of printed circuit boards has been widely used. The most common application is to carry out hole metallization, to complete the double-sided or multi-layer printed circuit board interlayer wire connection. In addition to the additional method of manufacturing printed boards with a single immersion of thick copper.

Application and Advantages of Chemical Copper Plating

Chemical copper plating is widely used in various industries, such as electronic and electrical appliances, hardware technology, handicrafts, furniture decoration, and so on. For example, copper plating on stainless steel surfaces, copper plating on circuit boards, copper plating on aluminum, copper plating on iron parts, copper plating on copper, copper plating on resin, copper plating on glass, copper plating on plastics, copper plating on diamond, copper plating on leaves, and so on.

Chemical copper plating is easy to operate, large-scale assembly lines can be operated, and small factories without equipment can also be operated. No electricity is needed. And environmental protection, no cyanide.

Chemical copper plating has high stability, a wide range of working temperatures, and solution concentration. The copper layer is dense and has excellent bonding force. These are the advantages of chemical copper plating.

It is basically suitable for copper plating on all metal and non-metal surfaces.

Bright Chrome is a Polished Chrome finish color. Chrome’s reputation for quality arises from the fashion for pure, contemporary lines. It gives the Coffee Machine Parts a sparkling which never dulls over time. Its versatility makes unlimited creativity possible when it comes to decorative touches.

Chrome Plating is created over a thick nickel underlay. It is a durable finish which is virtually impervious to wear or scratches. Its resistance to corrosion and common Coffee Machine products make it a benchmark in Home appliance decorations.

- Cleaning: Very easy

- Corrosion resistance:unexceptionable

- Scratch resistance: unexceptionable

- Resistance to cleaning products: unexceptionable

Share Electroless Copper Plating Plastic Panel | Chemical Copper Plating Plastic With Your Clients

Available Shipping Method

Ship By Air

Ship By Sea

Ship By Train

Ship By Express