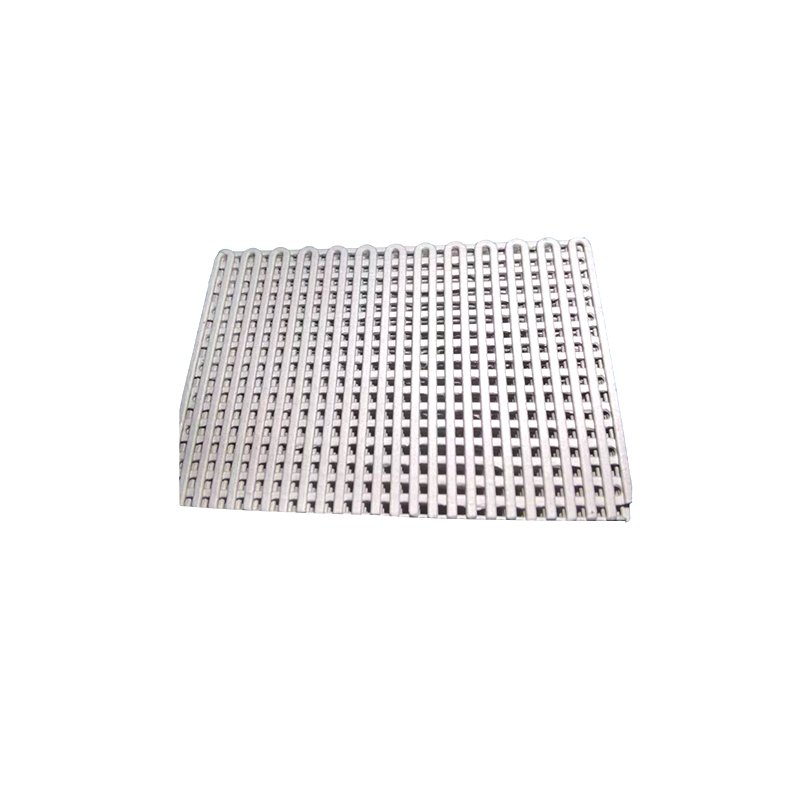

Electroless Nickel Plating Plastic Panel | Chemical Plating Plastic

| Material: | ABS, ABS+PC, NYLON, PC, PE, FPI |

|---|---|

| Process Might be Used | Brushing, Shielding |

| Mimimum Order Quantity | 10000pcs per Item for Bulk Order, 1000pcs per Item for trial Order |

| Sample Leadtime | 3-5 Days |

| Production Leadtime | 10-20 Days |

The Certificates We have

Details About Electroless Nickel Plating Plastic Panel | Chemical Plating Plastic

Introduction About Electroless Plating | Chemical Plating

Chemical plating is the fastest developing one. The plating solution is generally nickel sulfate, nickel acetate, etc. as the main salt, hypophosphite, sodium borohydride, borane, hydrazine, etc. as the reducing agent, and then a variety of additives. The operation is carried out in an acidic solution at 90℃ neutral solution or alkaline solution close to room temperature. It is divided into two categories, chemical nickel-phosphorus plating and chemical nickel-boron plating, depending on the reducing agent used. The plating shows superiority in uniformity, corrosion resistance, hardness, solderability, magnetism, and decoration.

Chemical plating is also known as electroless plating (Electroless plating), and can also be called autocatalytic plating (Autocatalytic plating) [1]. The specific process is: under certain conditions, metal ions in aqueous solution are reduced by a reducing agent and precipitated onto the surface of a solid substrate. Autocatalytic plating is defined in ASTM B374 (ASTM, American Society for Testing and Materials) as the “deposition of a metallic coating by a controlled chemical reduction that is catalyzed by the metal or alloy being deposited”. This process differs from replacement plating in that the layer is continuously thickened [2] and the applied metal itself has catalytic capabilities.

Under the catalytic effect of catalyst Fe, the hypophosphite in solution catalytic dehydrogenation on the catalytic surface, the formation of active hydride, and oxidized to phosphite; active hydride and nickel ions in solution for the reduction reaction and the deposition of nickel, which itself oxidized to hydrogen. That is.

2H2PO2-+2H2O+Ni2+→Ni0+H2↑+4H++2HPO32-.

At the same time, part of the hypophosphorous acid in the solution is reduced by the hydride to a single phosphorus into the plating layer. That is.

H2PO2-+[H+](catalytic surface)→P+H2O+OH-, the chemical plating layer formed is NiP alloy, amorphous booklet structure.

This is a method of depositing a layer of nickel on the surface of a workpiece by redox action without the use of an external electric current. It is used to improve corrosion and abrasion resistance and to increase luster and aesthetics. It is suitable for bright nickel plating of tubular or small parts with complex shapes without polishing. Generally, the plated parts are immersed in a mixed solution of nickel sulfate, sodium dihydrogen hypophosphite, sodium acetate, and boric acid, and then changed at a certain acidity and temperature, the nickel ions in the solution are reduced to atoms by sodium dihydrogen hypophosphite and deposited on the surface of the parts to form a fine bright nickel plating layer. Iron and steel parts can be plated directly with nickel. Tin, copper, and copper alloy parts should be first contacted with an aluminum sheet on its surface for 1-3 minutes to accelerate the chemical nickel plating.

Chemical plating is a method of obtaining metal alloys on plated parts with catalyzed surfaces using redox reactions without electricity. It is a new technology newly developed.

Chemical nickel plating after years of continuous exploration and research, in recent years has been the development of extremely mature, chemical nickel plating water is suitable for almost all metal surface nickel plating. Such as steel nickel-plated, stainless steel nickel-plated, aluminum nickel-plated, copper nickel-plated, and so on, it is also applicable to non-metallic surface nickel-plated. For example: ceramic nickel plating, glass nickel plating, diamond nickel plating, carbon nickel plating, plastic nickel plating, resin nickel plating, and so on. The scope of use is very wide.

Also applies to most of the plastic parts’ surface, mostly functional plating, that is, the non-conductive plastic parts become conductive. The appearance of the surface effect is not as good as water electroplating. Plating is more uniform, even inside the tube can also be plated.

Bright Chrome is a Polished Chrome finish color. Chrome’s reputation for quality arises from the fashion for pure, contemporary lines. It gives the Coffee Machine Parts a sparkling which never dulls over time. Its versatility makes unlimited creativity possible when it comes to decorative touches.

Chrome Plating is created over a thick nickel underlay. It is a durable finish which is virtually impervious to wear or scratches. Its resistance to corrosion and common Coffee Machine products make it a benchmark in Home appliance decorations.

- Cleaning: Very easy

- Corrosion resistance:unexceptionable

- Scratch resistance: unexceptionable

- Resistance to cleaning products: unexceptionable

Share Electroless Nickel Plating Plastic Panel | Chemical Plating Plastic With Your Clients

Available Shipping Method

Ship By Air

Ship By Sea

Ship By Train

Ship By Express