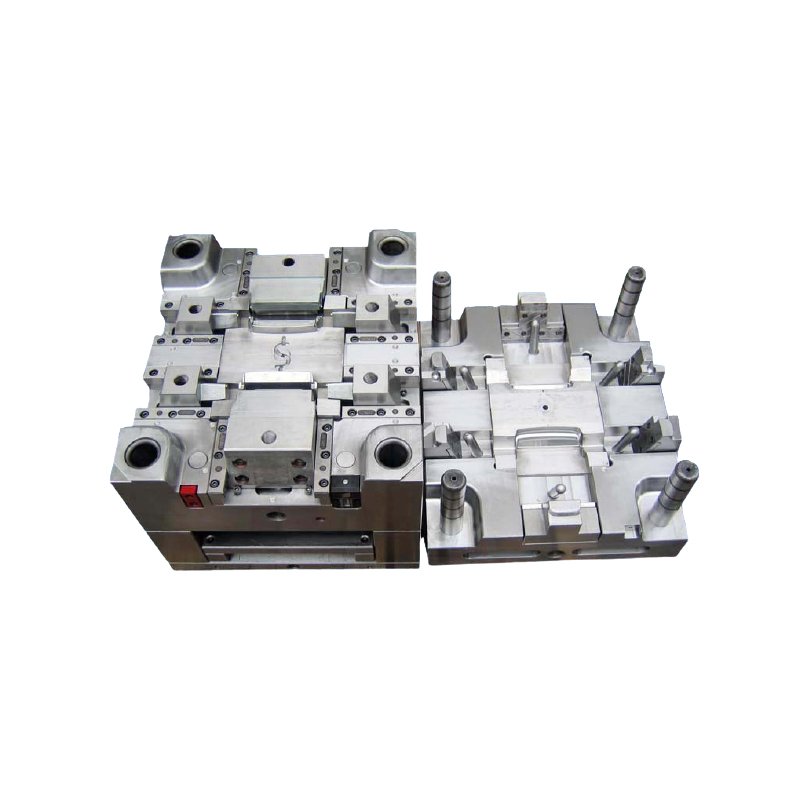

Plastic Mold Manufacturing

| Material | STEEL |

|---|---|

| Color | STEEL |

| Mimimum Order Quantity | 1 |

| Sample Leadtime | 45 Days |

| Production Leadtime | 45 Days |

The Certificates We have

Details About Plastic Mold Manufacturing

What should we pay attention to during the processing of plastic molds?

The following introduces the precautions during plastic mold processing:

1. Ensure the quality of raw materials and conduct corresponding inspections on raw materials to ensure that they do not contain impurities that may affect the plastic mold and are not contaminated or corroded.

2. During the processing, different products should be cut with different tools to avoid problems such as mold breakage or excessively deep knife lines.

3. The size of the plastic product mold should be determined according to its structural type.

4. During the processing, the mold needs to be cooled and insulated to keep the mold within the normal temperature range to avoid mold deformation.

5. In order to ensure the beautiful surface of plastic products, the mold should be made of stainless steel.

6. In order to facilitate the emergence of molds, plastic products should be preheated during processing to increase the attraction of plastic products to molds and prevent products from being damaged due to the emergence of bonded molds.

7. When processing plastic molds, the production cycle should be considered. Generally speaking, after the mold is manufactured, it needs to be tested. If there are no problems, you can start trial production.

8. During the processing of plastic molds, remember not to let water, dust, and other ingredients enter the mold, and do not let voltage or high current enter the mold for a long time to avoid damaging the appearance of the plastic product.

9. In order to ensure the good performance of plastic processed products, the processed products need to be dried and then injected into the mold to avoid problems such as gas emission and deformation inside the product.

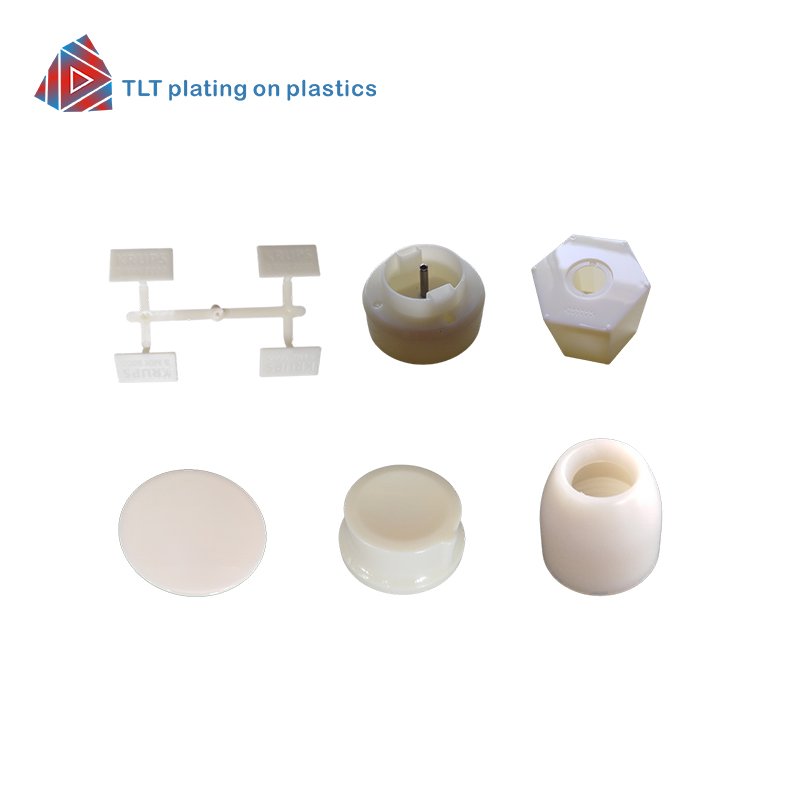

Bright Chrome is a Polished Chrome finish color. Chrome’s reputation for quality arises from the fashion for pure, contemporary lines. It gives the Coffee Machine Parts a sparkling which never dulls over time. Its versatility makes unlimited creativity possible when it comes to decorative touches.

Chrome Plating is created over a thick nickel underlay. It is a durable finish which is virtually impervious to wear or scratches. Its resistance to corrosion and common Coffee Machine products make it a benchmark in Home appliance decorations.

- Cleaning: Very easy

- Corrosion resistance:unexceptionable

- Scratch resistance: unexceptionable

- Resistance to cleaning products: unexceptionable

Share Plastic Mold Manufacturing With Your Clients

Available Shipping Method

Ship By Air

Ship By Sea

Ship By Train

Ship By Express