High-gloss plating

High-gloss plating is usually achieved by polishing the mould surface well and injecting the part with a bright chrome finish.

Matt plating

Matte plating is usually achieved when the mould surface is well polished and the injected part is treated with a sub-chrome finish.

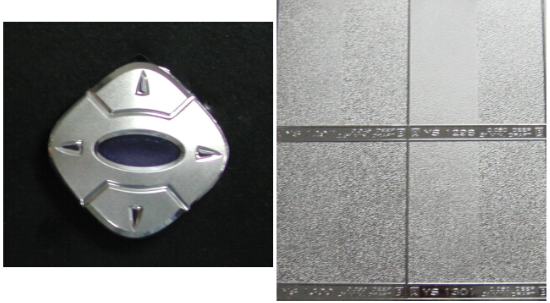

Pearl Chrome

The effect of pearl chrome plating usually requires a good polish on the surface of the mould and the injected part is treated with pearl chrome.

Etched plating

The effect of etched plating usually requires the surface of the mould to be etched in a different way and the injected part to be treated with bright chrome.

Mixed plating

In moulds with both polished and etched parts, injected parts are plated with a mixture of high gloss and etched plating to highlight certain local features.

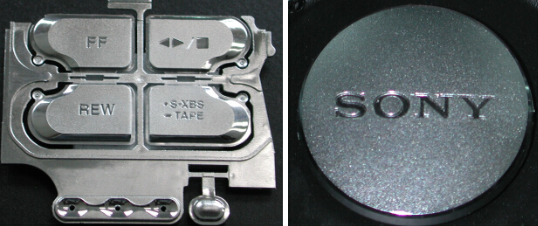

Partial plating

By using different methods, the surface of the finished part is partially unplated to create a contrast with the plated parts, creating a unique design style.

Colour Plating

By using different plating solutions, the metal deposited on the surface of the plated part will reflect a different lustre, creating a unique effect.